The project

GoodByO

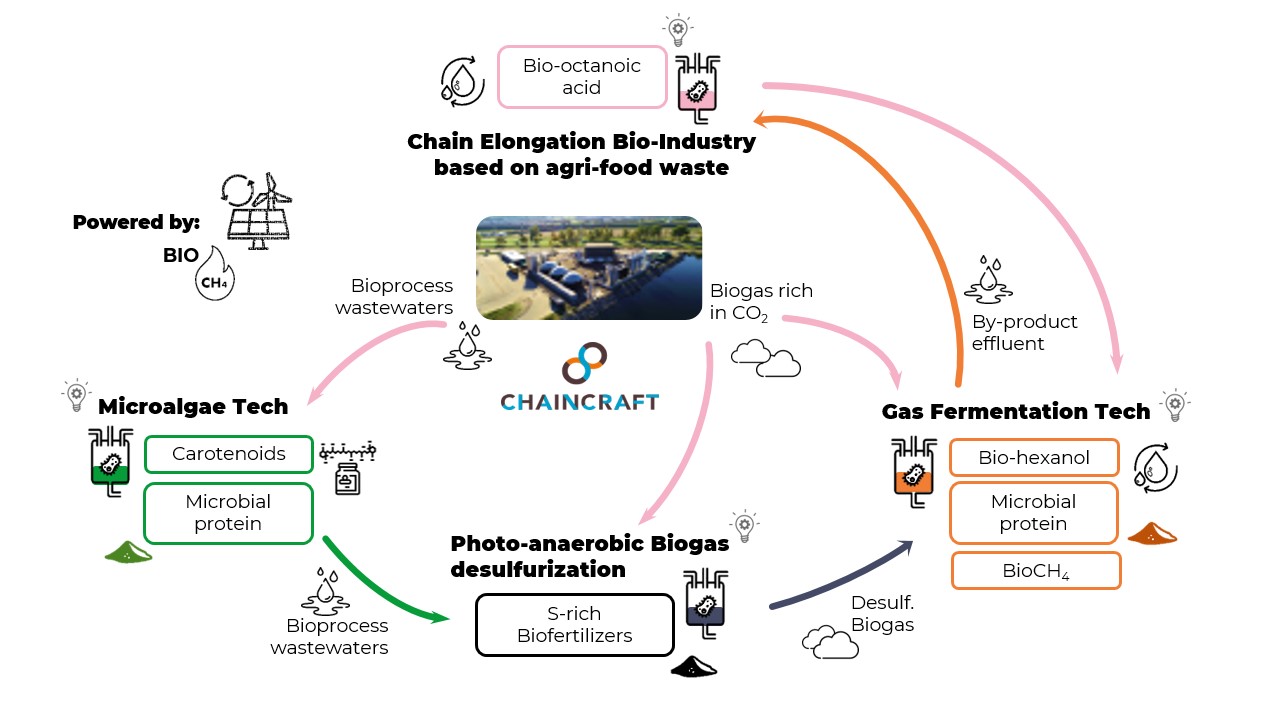

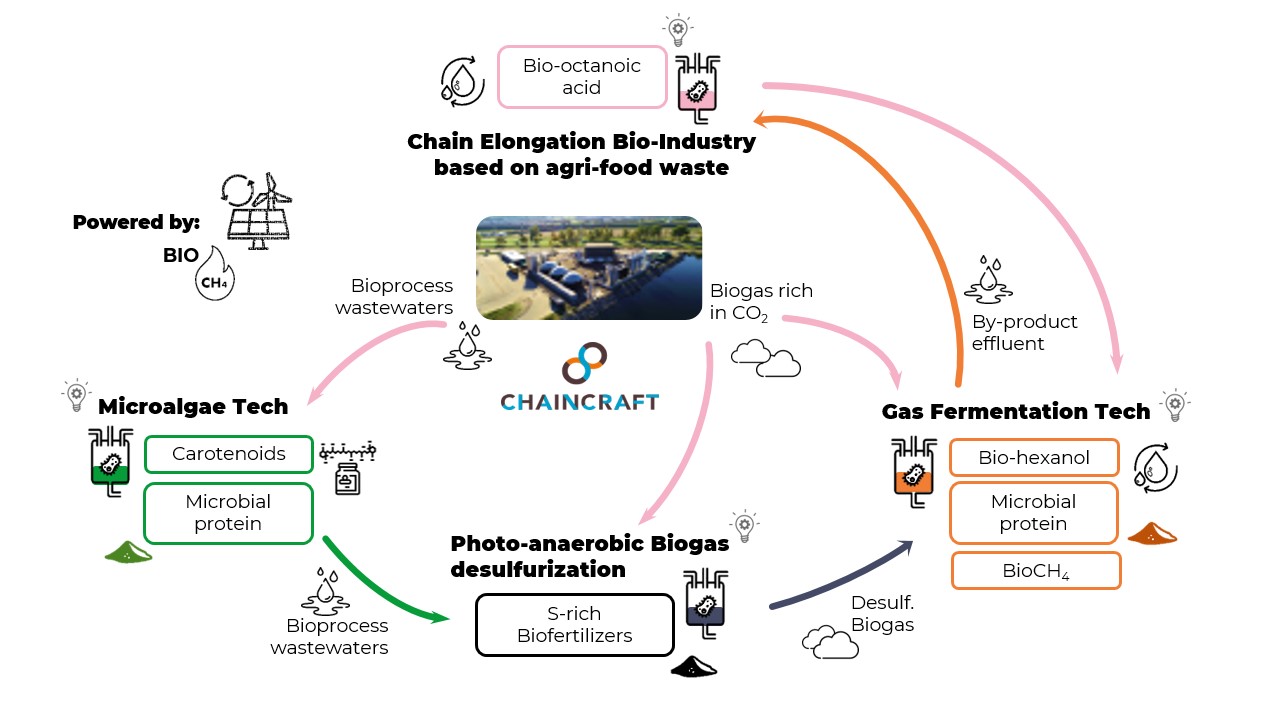

GoodByO – Creating a Multi-commodities microbial-driven biorefinery based on food-processing industry wastes, biogenic carbon dioxide and bioprocess wastewaters is a project founded by the the Circular Bio-based Europe Joint Undertaking work programme. The project aims to create a new generation biorefinery using food waste, biogenic CO2, and bioprocess wastewaters to produce bio-based products.

GoodByO ambitions will be realized by achieving the following specific objectives:

Creating a microbial chain elongation technology to produce large-scale bio-octanoic acid from agri-food waste and gas fermentation effluent, while generating two residue streams as zero-cost feedstock for other GoodByO microbial factories

Developing a novel gas fermentation process using acetogenic bacteria for bio-hexanol production from biogenic CO2 (biogas) and green H2

Establishing a cost-effective microalgal carotenoid production process leveraging bioprocess wastewaters and an innovative photo-bioreactor system

Developing a novel biological anaerobic biogas desulfurization process combined with sulphur-rich microbial biomass recovery

Validating the long-term stability of developed biocatalysts and continuous bioprocesses using real feedstocks to achieve consistent and scalable production performance

Designing a renewable energy-based power supply system for the multipurpose biorefinery, using biomethanation as intermediate energy storage

Ensuring environmental benefits of GoodByO technologies compared to the current commercial processes

Developing a consolidated roadmap for GoodByO technologies scale-up and commercialization.

Short term

Outcomes

Technologicals outcomes:

Novel energy-independent holistic biorefinery concept featuring enhanced environmental performance, and maximizing resource and energy efficiency. This approach harnesses the metabolic diversity of microorganisms and optimizes the cascading utilization of bio-based feedstocks, including agri-food wastes, biogenic CO₂, and bioprocess wastewater.

Setting an example for biorefineries and showing the feasibility and viability of integrating different microbial-based manufacturing processes.

Economic outcomes:

Generating sustainable bio-based products at cost competitive selling price with benchmarks, as much as possible, in order to boost end users companies in substituting fossil- and palm-oil based products with bio-based ones.

Environmental outcomes:

Promoting the use of biogenic CO2 streams and biorefinery waste effluents as zero-cost feedstocks.

RES-based bioprocesses with reduced GHG emissions, reduced waste production/disposal and increased water-recycling, compared to current benchmarks processes.

Long term

Impacts

Technological Impacts:

Consolidating EU research and infrastructural leadership in Biotech, Circular Bioeconomy and CCUs fields. Integrating between Biorefinery and RES sectors.

Environmental Impacts:

Industrial/Economical Impacts:

Consolidating EU global leadership in Manufacturing Biotech-Industry:

Promoting the chemical storage of green H2 within consumer goods.